Need a prototype? A small run? A thousand parts?

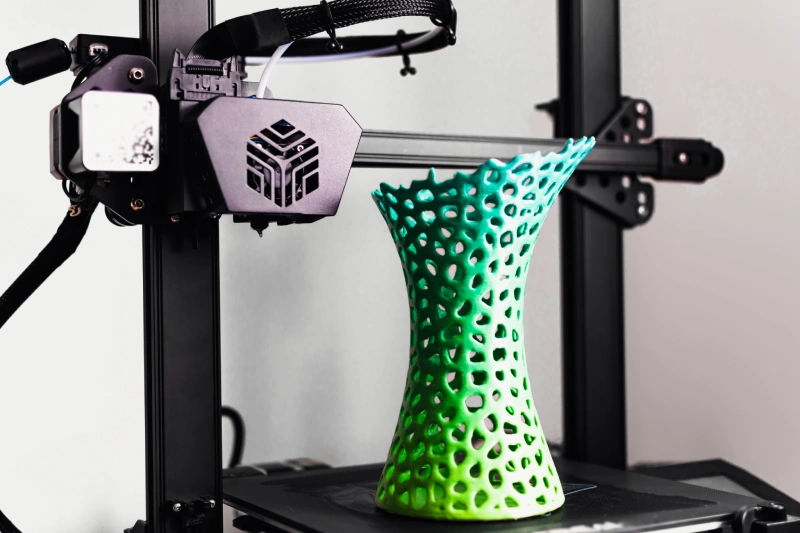

We’ve got you covered. Our services include precision CNC machining, sheet metal fabrication, welding, 3D printing and mechanical assembly, all built to your exact specifications. Whether you’re scaling up or building one perfect part, we deliver consistent results, tight tolerances, and reliable turnaround.

Custom-built enclosures

Wiring, PLC mounting, and component integration

Compliance with industrial standards and safety protocols

CNC machining, laser cutting, sheet metal fabrication

Design-to-fabrication workflow for high-precision components

Mechatronic system builds

Subsystem assembly for automation equipment

Pneumatics, sensors, actuators, and drives integrated in-house

Short-run production for testing, R&D, or pilot projects

Rapid design iterations supported by our engineering team

Short-run production for testing, R&D, or pilot projects

Rapid design iterations supported by our engineering team

Short-run production for testing, R&D, or pilot projects

Rapid design iterations supported by our engineering team

Show respect to your seniors, with even greater respect for those from whom you learn. Treat subordinates with kindness and dignity.

No one is a boss, and no one is opposition — we work as close friends, supporting each other whenever needed.

Before business, always ask: What value can we add to help the customer grow faster, gain more with little effort and existing resources?

Seek out innovative solutions. Embrace creativity and think beyond the conventional.

Own your actions and take responsibility for the outcomes.

Support young talent when they reach out for guidance. Solve real-world problems through engineering.

Got questions about Meckatron? We’ve got the answers—clear and reliable.

We handle both. You can come with a new idea or ask us to improve something that already exists. We help with updates, feature additions, or fixing design issues at any stage.

DFM is part of our design process from the beginning. We focus on how the product will be made, its cost, and how easily it can be produced, along with how it looks and works.

We offer both. You can start by testing a prototype with us and move to full production when you're ready. After the design phase, we build and test physical prototypes. First, we create an alpha version to check functionality. Then we make a beta version that closely matches the final product in appearance and performance. A small batch is also made for real users to test before full production.

Our team considers real manufacturing needs like materials, cost per part, and production methods from the start. We also run simulations and work with suppliers to avoid problems later.

Your data is kept private and safe. We use NDAs and give file access only to those working on your project. We follow US legal standards as we are a registered business in the United States.

We work with trusted suppliers we have known for years. We check their quality, pricing, and capacity. Our engineers also work with them to choose the right materials and production methods, and we keep you informed at every step.

We choose the right materials and use simulations to make smart design decisions that lower costs before production starts. Quality is always maintained.

Send us a message and our team will respond within 24 business hours.

Our support team is available 24/7 to assist you with any questions or concerns.